Within this embossed velvet box lies a supreme quality desk-set.

Of superior quality, this set is made to impress. From the shape of the letter-opener and the detail of the engraving, it was ‘exotic’, reflecting the riches of the Eastern cultures – it would not have been out of place in the courts of Suleiman the Magnificent, ruler of the Ottoman Empire in the 16th century.

But clearly, this example was made in the second half of the 19th century.

The clue to who, when & where is found on the nib of the pen. The inscription there reads ‘RICHARD MOSLEY & Co. / LONDON’ . The nib was English made – and the style of the piece, while possibly attributable to a French workshop, could also be English. A little more research reveals a fascinating story that supports this attribution.

Richard Mosley & Co.

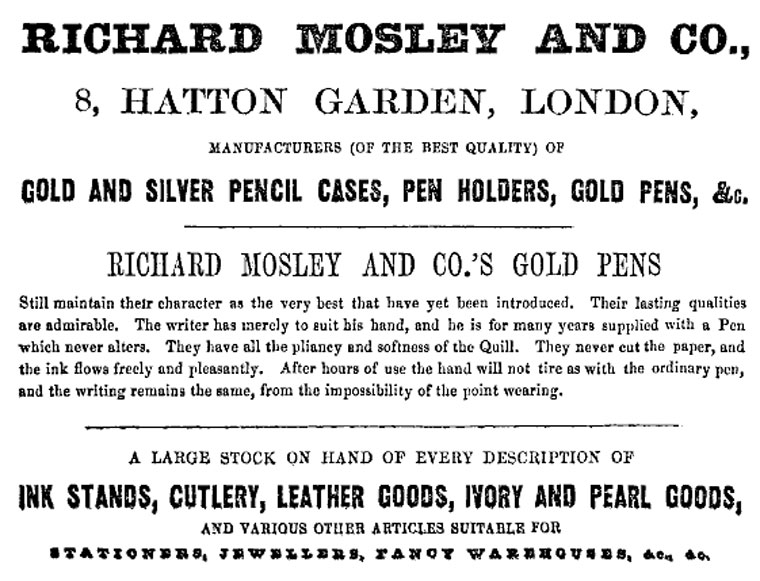

Richard Mosley was the son of Richard Mosley, silversmith in London, and became a supplier of superior writing implements by the mid-19th century. In his 1852 London Directory advert he states he supplies superior steel nibs that do not wear, as seen on the pen in this set. He also states he stocks a “A LARGE STOCK ON HAND OF EVERY DESCRIPTION OF INK STANDS, CUTLERY, LEATHER GOODS, IVORY AND PEARL GOODS, AND VARIOUS OTHER ARTICLES SUITABLE FOR STATIONER & JEWELLERS”. Clearly, these were not all manufactured by him, but sourced from various workshops and retailed by him – once he had included one of his superior non-wearing nibs.

His secret to a superior product was to embrace the latest technology: stainless steel. This was the ‘holy grail’ of industry in the 19th century, to have a durable steel product that would resist rust. By embracing a new technology, he was able to produce a novelty ‘tech gadget’ of his time.

The method of decoration is acid-etching steel. This technique was exhibited at the 1851 Great Exhibition by Thomas Skinner of Sheffield. He had obtained a patent the same year for an efficient way of producing complex etched designs on steel, which could then be enhanced with gilt, as seen on our desk set.

The technique used was simple and efficient for such complex designs, previously only possible at the hand of a master-engraver. Basically, a copper plate engraving of the required design was printed onto tissue paper (such as potters use for transfer printing) – in ink & linseed oil, which could then be pressed onto the steel surface; once this had hardened, water applied to the paper allowed it to be peeled off. A powdered ‘resin’ was then dusted over, binding with the sticky linseed oil/ink. Applying hot water solidified the design in the same places into a hard crust, resistant to acid. This was then ‘bitten’ – the very descriptive term used by engravers for the action of acid onto metal! Once cleaned off, the acid etched depressions could be gilded, and a low temperature firing in a kiln ensured a strong bond for the gold.

The Mosley firm exhibited pens in the 1851 Great Exhibition, but did not win a medal. Curiously, they did not enter their pens into the ‘Iron & General Implements / writing implements’ category (Class 22), but rather in the ‘precious metals’ category (Class 23, exhibitor 107) – such was their regard for the quality of their products. This set is certainly ‘exhibition-worthy’, but the question of wether it was a Mosley product or if he just added one of his tips to a fine quality Sheffield product made using Skinner’s patent remains debatable.